Add to Cart

PU Sandwich wall panels are widely used in commercial and industrial building construction as external wall. Due to the excellent performance of the insulation, PU(polyurethane) sandwich panels are commonly adopted for heat insulation and deadening applications in these buildings,such as food cold stores,industry halls, warehouses, logistic centers, offices, sport halls as well as rural buildings.

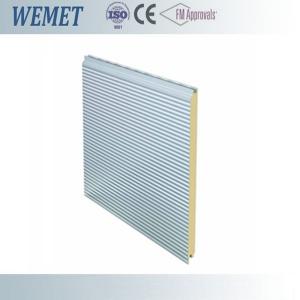

Wemet Industry’s sandwich panels consist of two steel sheets facings and an insulation core.Panel facings are made of galvanized steel sheet, coated with polyester paint, thickness from 0.3 to 0.7 [mm] made in accordance with norm PN-EN 10346:2009. The steel we use to produce our panels are delivered by top china steel suppliers.

The core of the panel can be made of polyurethane (PUR) foam with density of about 40 ± 2 [kg/m3] or more is produced by our own factory.

It is a highly heat insulating wall plate system with excellent flexural capacity. It is preferred for the walls of high-end buildings

| Item | Specification |

| Product name | Cold room panel |

| Structure | PPGI + Polyurethane foam/PIR foam+ PPGI(PPGI prepainted galvanized steel sheet |

| Effective width | 1000mm |

| Panel Thickness | 30mm, 50mm, 60mm, 75mm, 100mm, 150mm, 200mm |

| Length | Customized |

| Core | Rigid polyurethane foam |

| Density | 40-42kg/m³ |

| Thickness of steel | 0.4-0.7mm |

| Color | Blue, white grey, red and other colors in RAL |

| Thermal | 0.023% w/(m`K) maximum |

| Enclosed rate | 98% minimum |

| Flame resistance | Grade B |

| Usage life | Over 20 years |

Product advantages of PUR(polyurethane) sandwich wall panels

1. The products are connected by blind nails and have no exposed screws on surfaces, promising beautiful and smooth appearances for walls of buildings.

2. Their extremely great flexural capacity and excellent mechanical properties can lower the dependence on auxiliary steel structures

3. Their excellent heat preservation performance can cut down the cost of the interior air-conditioning devices of buildings.

4. There are multiple appearance effects (ripple effect, plat effect, relief effect and square wave effect) for your choice to make wall surfaces beautiful

5. Energy-saving & insulated

Excellent insulation properties (average thermal conductivity is 0.020W/m.k). In the protective effect of formula and outer color steel plate based on the stable condition, in three years, its thermal performance can still keep its first 180 days of the above thermal insulation performance of 95% core obturator rate >=97%

Comparison of PUR(polyurethane) sandwich wall panels with other materials.

Techincal parameters of PUR(polyurethane) sandwich roof panels

Production process of PUR(polyurethane) sandwich roof panels

Step1. Spread galvanized steel----Step2. Profiled panel----Step3. Heat the panel----Step4. Foam mixture----Step5. Spraying the black and white materials----Step6. Shaped already----Step7. Cut the panel----Step8. Put panels in order.

Application of PUR(polyurethane) sandwich wall panels

Package and Loading of PUR(polyurethane) sandwich wall panels

All the structure components, panels, bolts and sorts of accessories will be well packed with standard package and it is suitable for ocean transport.

All the products are loaded at the loading site of our factory using crane and forklift byour skilled workers, who will prevent the goods to be damaged.

We have Good relationship with many vessel companies so that we can make sure the transportation smooth.