Add to Cart

The choice of cold storage panel is very important for the cold storage, cause the cold storage is different from the ordinary warehouse, the temperature inside the cold storage is generally low, and the requirements for air temperature, humidity, and environmental are relatively high. So we must pay attention to the cold storage panels when choosing the cold storage panels. If the cold storage board is not well selected, the temperature inside the cold storage is difficult to control, the products stored in the cold storage easily go bad, or let the cold storage refrigeration compressors work frequently, waste more resources and increase costs. Choosing the right cold room panels will better maintain the cold storage.

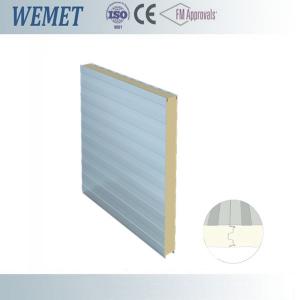

Product advantages:

A. The tongue and groove joint structure improves the insulation and air tightness of the panels and is specially designed for cold storage.

B. The panels are uniform and stable and extremely excellent in both heat insulation and water proofing.

C. The panels have light weights and beautiful appearances, solving the temperature difference problem of the cold storage industry effectively.

D. Within certain modulus, the cold storage may change freely in length, width and height directions to get bigger or smaller according to actual needs. The knockdown boards may be remounted at another place conveniently and quickly.

The technical specifications of cold storage sandwich panel

| Item | PU/PIR cold room panel |

| Usage | cold room |

| Joint details | Tongue and groove |

| Cover width | 1000mm |

| Thickness | 100mm/125mm/150mm/175mm/200mm |

| Cut length | 1-11.8m, customized |

| Insulation density | 35-42kg/m3 |

| Facial Material | PPGI/PPGL:0.4-0.8mm (PE, SMP, PVDF, Zinc coating 30-275g/m2) |

| Stainless steel:0.4-0.8mm | |

| Aluminum sheet :0.5-1.0mm(AZ50-150g/m2) | |

| Color | Ocean Blue ,Grey White, Red or RAL |

| Packing | Protecting PVC film on both sides |

| Price terms | FOB,C&F,CIF |

| Payment terms | TT ,L/C ,Western Union |

| Delivery time | 7-10 days after confirmation |

| Thickness range | Temperature difference between inside and outside | Height of wall panel | Length of roof panel | Applicable cold storage temperature |

| mm | oC | m* | m** | oC |

| 100 | 30 | 5 | 4.45 | -15 |

| 125 | 35 | 5.5 | 5.2 | -20 |

| 150 | 50 | 6 | 5.85 | -25 |

| 175 | 65 | 6.5 | 6.3 | -30 |

| 200 | 75 | 7 | 6.8 | -40 |

A. The data shown in the left table are only available for the panel which subject to the internal-external pressure difference and contraction pressure, without wind load. If the specified length/height is exceeded or wind load occurs, panel supporters are required.

B. The above data are calculated according to the heat flow of 8~10W/m2.

Panel joint of cold room sandwich panel:

Raw material of PUR/PIR cold room sandwich panels

Application fields:

● Fast frozen processing and refrigeration of food

● Food processing plant

● Storage of dairy products

● Biological products and medicines

● Indoor cold storage

● Cold storage for cold-chain transportation vehicle